Ink type : Urethane based two-part isocyanate hardening inks.

Usage : Applicable on hard-coated acrylic surface(such as MR200 manufactured by Mitsubishi RAYON)

Feature : Excellent leveling properties, semi-gloss finish, outstanding rub-resistance.

Diluents : Standard solvent : T-926,T-945

Slow dry solvent : T-927

Retarder : T-980

Hardener : N hardener, standard hardener, used in regular circumstance

D hardener, use to improve rub-resistance.

Mixing ratios: Ink: Hardener =100:10

Gel phenomena may occur after 6-8 hours of usage at room temperature after mixing,

leading to Reduced physical performance.

Wash-up : T-31/T-15

Screen mesh: 200-300 mesh / inch polyester or Nylon screens is recommended.

Drying time : Air drying: sets to touch in 40minutes at 20¡æ.

Thermal curing: 30minutes at 80¡æ+1day air-drying.

Notes : N-hardener is extremely sensitive to moisture£¬ please use as soon as possible after opening.

Rate of evaporation has been reduced to improve printability, thermal curing is recommended.

During multi-layer printing, it is recommended for previous layers to be set to touch dry,

and hard-dried after all procedures are completed to prevent peeling.

Color code for HF BMR-S Series.

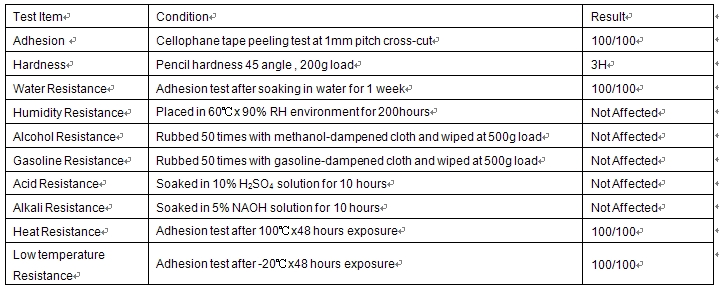

Ink Layer performance.

Test Conditions

Ink : HF BMR-S 120 White, 710 BLACK

Drying : 30minutes at 60¡æ and air ¨Cdrying for 1 day.

Material: MR200